Autodesk is delivering on its promise of having design and 3D printing solutions easier and more accessible to everyone. Although the industry is in its infancy stage in the Philippines, it has started to take off with the availability of affordable 3D printers, downloadable models, and the improvement in design capabilities that will empower 3D printing.

In an interview with UpgradeMag.com, Chris Lee, Regional Industry Manager (Manufacturing), ASEAN, at Autodesk, discussed the factors driving 3D printing adoption in the Philippines, and mentioned that Autodesk is bent on delivering the benefits of 3D printing.

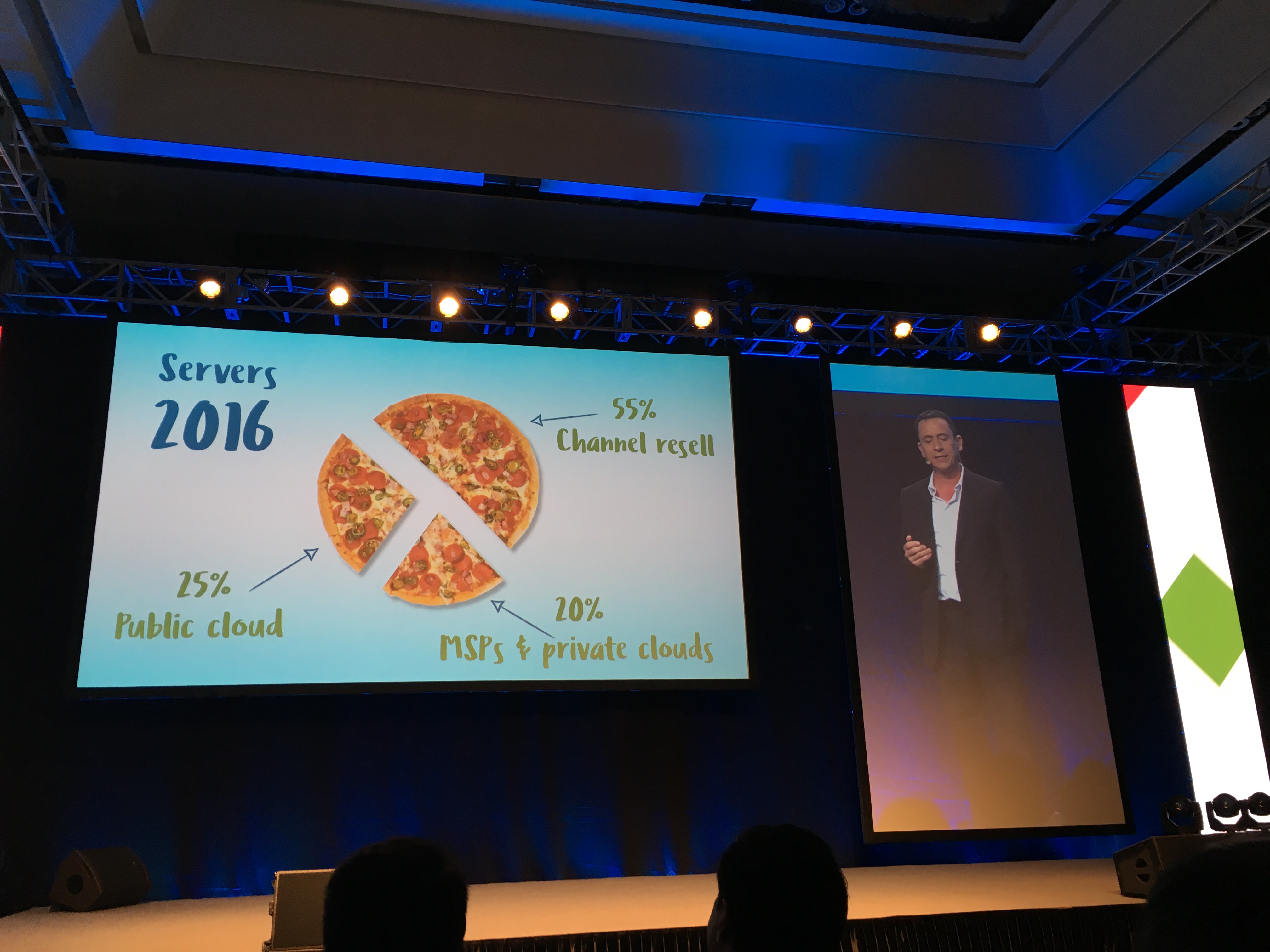

Around the world, 3D printing has come of age, surpassing $1B in revenues during 2012 and with growth expected to continue across all target markets to 2025. Across the board printer manufacturers are reporting a surge in sales, some cannot meet demand, as awareness of the technologies and what they offer grows.

According to IDTechEx, 3D printing opens up the opportunity for the introduction of cheap complexity into manufacturing. Unitized, albeit currently relatively small, structures can be printed which either could not be manufactured via alternative means, or would have been prohibitively expensive to do so.

In 2011, KOR EcoLogic used Autodesk’s software solution for Digital Prototyping to design the first prototype car with a body created using a 3D printer.

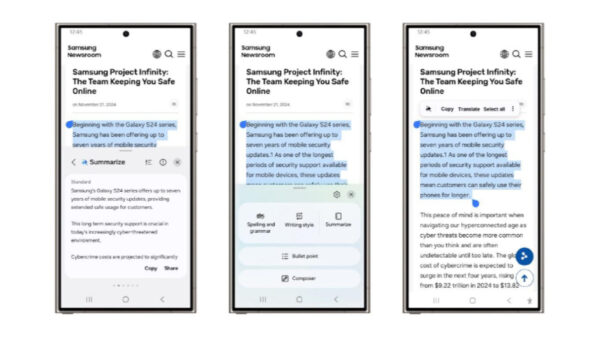

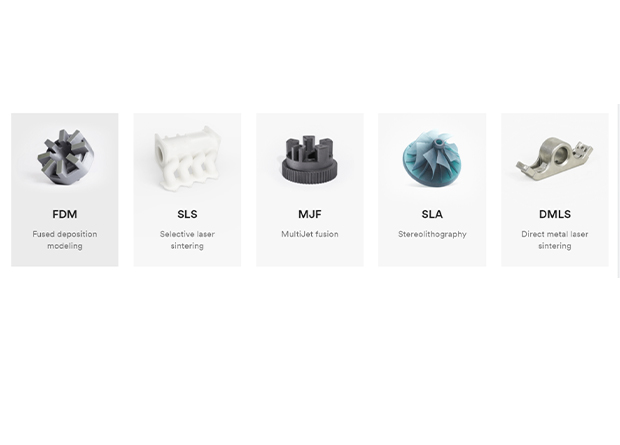

3D printing, also known as additive manufacturing, is a prototyping process, whereby a real object is created from a 3D design. “The model design can be printed in plastic, and in other materials,” said Lee. Model designs can either be manufacturing prototypes, consumers’ products and even human organs using a person’s own cells. In fact, according to Lee, Autodesk is geared towards exploring the extensive possibilities of 3D printing in the medical field when it partnered with Organovo.

Lee mentioned that a designer doesn’t have to be an engineer or a 3D modeling expert to create 3D models. “Anyone can do it. There’s no training involved or technical skills needed. If he wants to try or is just getting started, Autodesk has a model repository which can be downloaded for free,” says Lee.

Transforming traditional manufacturing processes

Lee also noted that 3D printing is capable of transforming traditional manufacturing processes to concrete modern designs. Customers can design and customize their own product, choose the colors, materials and personal identification before it gets manufactured. This function moves 3D printing away from the mass production activity to customizable one-shot production.

The company, Lee notes, is introducing new digital prototyping solutions that offer businesses unprecedented access to the Autodesk portfolio, combining the power of desktop and cloud to more efficiently design, build, innovate, and deliver better products faster at reduced costs.

Among the new solutions is the Autodesk 2014 Design Suite which is intended for the manufacturing industry. The software consists of the Autodesk Product Design Suite and the Autodesk Factory Design Suite that provide designers and engineers with a complete set of tools and cloud services to simplify design, visualize and simulate workflows from product development through delivery.

Cloud and mobile platforms

Autodesk has also the capability of making design more accessible through cloud computing technology and mobile platforms. Autodesk Cloud 360 is a cloud-based platform for accessing Autodesk cloud services. Through this platform, a user can access free basic services and download free mobile applications for collaboration, file viewing and storage at anytime.

Autodesk Cloud 360 helps create a more collaborative platform where designers and manufacturing practitioners can work together on their respective workflow. In addition, Lee also mentioned how manufacturing is starting to get democratized by the growing popularity of 3D printing, from which Autodesk can help in the design process.

The introduction of these design software in the local market is considered very timely as, according to Lee, the Philippines has the potential of becoming a leading player in the manufacturing industry in the ASEAN.

Based on the statistics from the National Statistical Coordination Board (NSCB), the Philippines emerged as the fastest growing economy in Asia with its manufacturing sector growing 9.7% in the first quarter of 2013. The country’s gross domestic product (GDP) also grew by 7.8% in the first quarter of 2013, higher than China’s 7.7%, Indonesia’s 6%, Thailand’s 5.3%, and Vietnam’s 4.9%.

The positive development about 3D printing was also driven by another annual in-depth study, or the so-called Wohlers Report, which estimates that additive manufacturing will be a $3.1 billion industry by 2016 and a $5.2 billion industry by 2020.

Aside from manufacturing, Autodesk suites also work together seamlessly for other industries as well. Currently, the company caters to the following industries: architecture, engineering and construction; media and entertainment; natural resources (mining, oil and gas); civil infrastructure including utilities and telecommunication; and education.

Free design software for students

Meanwhile, Autodesk announced that it offers free design software for students. Students can download free software and access to cloud services and training, and tutorials provided this may not be used for commercial or for-profit purposes.

Autodesk also offers software rental license plans, which allow users to use Autodesk software for a specific period of time, either monthly, quarterly, or annually, with the option to renew. These plans are presented in addition to the company’s traditional perpetual software licenses, providing benefits similar to a perpetual license with Autodesk subscription.

Autodesk design software are currently available in the Philippines through its resellers, Tech Converge, Inc. and Global Sapphire. The cost of software ranges from a low of $6,000 to $12,000.