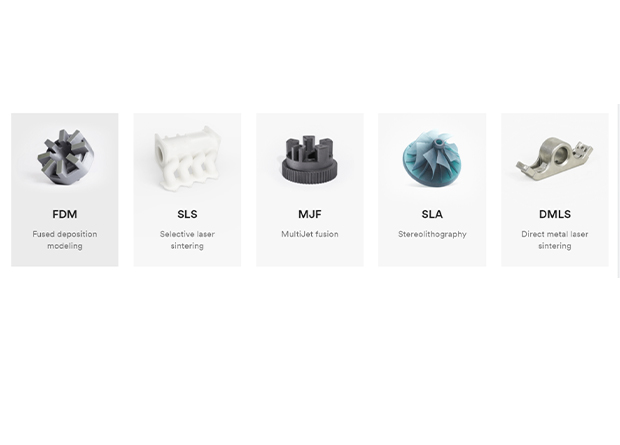

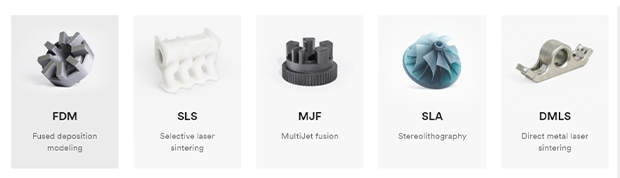

3D printing is nowadays one of the most popular manufacturing methods. It can be used to produce a ton of different items, which can also be done by a3D printing service UK. This way3D printing London is possible for you if you are not the owner of a special 3D printer. 3D printing can be done on several levels: industrial, personal, or local. Whatever level your project is, 3D printing certainly brings an amount of benefits that traditional manufacturing or prototyping processes simply cannot. In this article three of these benefits will be introduced.

Complex

The rise of 3D printing has seen a proliferation of products which involve levels of complexity that could not be created physically in any other way. This advantage has been taken up by artists and designers in order to create amazing visual effects. However, it also has made a big impact on industrial applications. These can now be developed to materialize complex components. These are proving to be both stronger and lighter than their predecessors. This is also the reason why 3D printing is starting to be used more and more in the aerospace industry. Here the weight and strength of a component play a massive role.

No tools

For industrial manufacturing, one of the worst stages of the product development process is the production of the tools. This is extremely intensive when it comes to costs, time, and labor. 3D printing can eliminate the need for tool production, so the costs, lead times, and labor will be eliminated as well. This is a very attractive proposition for companies. An increasing number of manufacturers are taking advantage of it. On top of that, due to the complexity advantages explained before, parts and products can be designed specifically to avoid assembly requirements. This way, it will further eliminate costs, time, and labor.

Sustainable

3D printing is emerging as an energy-efficient technology as well. It can provide environmental efficiencies in terms of both the manufacturing process itself. This is the case since it uses up to 90 percent of standard materials, so it creates less waste. Throughout an additively manufactured product’s operating life 3D printing provides environmental efficiencies too. This is done due to the lighter and stronger designs. This imposes a reduced carbon footprint compared with traditionally manufactured parts. Sustainability is, of course, extremely important at the moment.