By Sakari Kuikka, General Manager at Universal Robots, SEA & Oceania

An audio-visual device manufacturer in Indonesia has transformed its production floor, bringing together manual and automated processes. While workers take charge of detailed and dexterous tasks, such as quality control checks and programming the machines and robots, collaborative robots (cobots) carry out repetitive and hazardous jobs such as screwing and soldering.

This may contradict the conventional wisdom that disruptive technologies, such as robotics, will make some jobs redundant.

According to the ManpowerGroup, automation will not cause job losses, but increase opportunities in the future, as employers plan to increase or maintain headcount as a result of automation[1]. Asian economies are also showing similar trends. The Asia Development Bank notes that robotics adoption and other connected systems stimulated higher productivity and economic growth, creating 134 million new jobs.

While the Philippines can benefit greatly by embracing Industry 4.0, there is still a concern in the workforce that this could lead to job displacements and widen skills gaps.

A New Way of Working

As more and more manufacturers embrace automation to increase efficiency and save costs, there has been less optimism among workers who worry that robots will replace them.

However, a new school of thought is gaining ground. The manufacturing robots of the future will work alongside people, not replace them. This future is collaborative robots (cobots), robots designed to work side-by-side with people.

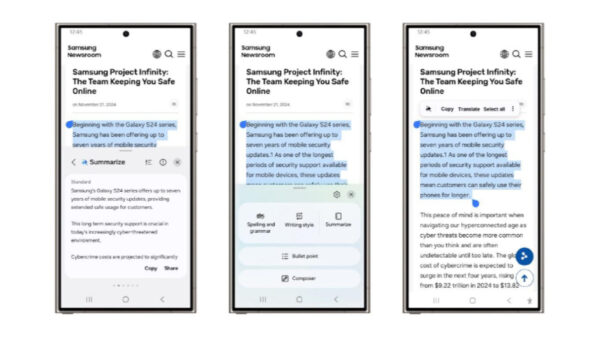

Not only are cobots compact, safe and flexible in deployment, but their intuitive programming also shortens the learning curve so that even lower-skilled employees can easily learn to use them.

The engineering team at PT JVC Electronics Indonesia, though new to robotics, fully understood the Universal Robots (UR) cobots within a month. Following that, the team successfully installed and programmed the cobots into their production line within a few months.

While humans bring their unique, cognitive skills to the table, robots deal with the requirements for heavy lifting, consistent quality, round-the-clock shifts, and sometimes dangerous tasks. At UR, we coined this thinking as Industry 5.0 – robot capabilities and human skills converging to get the best of both.

With cobots, employees are freed to upskill themselves into higher value responsibilities such as designing and implementing solutions to improve business capacity or improving their manufacturing processes using automation and robotics.

Raising Robotics Literacy

Cobots are a game changer in industrial robotics, illustrating how automation can be used to enhance rather than replace workers. To strengthen this perspective, UR has taken the industry lead by launching the UR Academy to aid businesses in robotics adoption. This high calibre robotics training is free of charge to anyone, with nine online modules that make up the basic programming training for UR robots. This includes adding end-effectors, connecting I/Os, creating basic programs, and setting up tools and safety zones. Rather than simply transferring information, the modules are built to deliver hands-on learning via interactive simulations to maximise user engagement. More than 51,000 users from over 130 countries have signed up so far for the training which is available in 8 languages: English, Spanish, German, French, Chinese, Japanese, Korean, and Thai.

UR also launched an in-class robotics training in Singapore. This training is open to the public and welcomes international participants.

In the Philippines, the Technical Education and Skills Development Authority (TESDA) recently launched its five-year national technical education and skills development plan (NTESDP) to address the challenges posed by the automation age. Through the plan, TESDA offers a wide range of training options to help develop work-ready and globally competitive workers.

Automation to Strengthen the Workforce

It is estimated that automation could displace up to 4.5 million workers or over 10 percent of the workforce. This includes 380,000 workers within the manufacturing industry. This need not be the case for the Philippines.

The country should adopt an alternative model of automation – Industry 5.0 – where people and cobots work together to revolutionise the production process, drawing on each other’s strengths. Beyond enabling workforce upskilling, cobots can also assist to improve workers’ performance and provide greater safety, resulting in an all-round higher satisfaction at work.