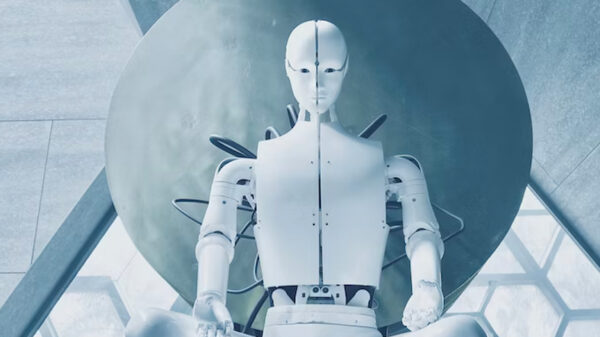

Universal Robots, maker of collaborative robots (cobots), has introduced its new flagship e-Series cobots. The new range follows Universal Robot’s co-founder, Esben Østergaard being awarded the 2018 Engleberger Award, the ‘Nobel Prize’ of robotics.

The new e-Series cobot platform includes technology advances that enable faster development for a wider variety of applications.

This new e-Series cobot platform includes technology advances that enable faster development for a wider variety of applications. Improvements include the ability to economically address even more applications, thanks to greater precision and sensitivity provided by a built-in, tool-centric Force/Torque sensor.

Like other Universal Robots offerings, the new e-Series takes just one hour to unpack the cobot, mount it and program the first task. A wrist-join-tool communication interface reduces production line integration time and complexity. Meanwhile, from a service standpoint, all joints can be replaced in 2 to 6 minutes.

A re-designed intuitive and responsive-touch user interface expedites program development by simplifying programming to a few clicks on a new lightweight, wide-screen Teach Pendant.

17 safety functions, including customisable stopping time and distance, make collaborative automation easier. Certified by TÜV Nord all these functions are in compliance with the EN ISO 13849-1 and EN ISO 10218-1 (Cat. 3 PLd) machinery safety standards for unobstructed human-robot collaboration.

Looking at the big picture, e-Series users can expect a fast return on investment, a cobot system ready for any future application, and long-term productivity gains.

“Our e-Series platform is leveraging our years of experience as the market leader within collaborative robots,” says Jürgen von Hollen, President of Universal Robots. “The ‘e’ in e-Series underpins our key vision and overall product philosophy, specifically Empowering people and making it Easy for Everyone.”

With the e-Series launch, Universal Robots now provides two different technology platforms. For customers interested in cobot capacity expansion for proven applications, the G3 is an ideal choice. The e-Series benefits businesses with advanced applications and diverse or uncertain future needs.

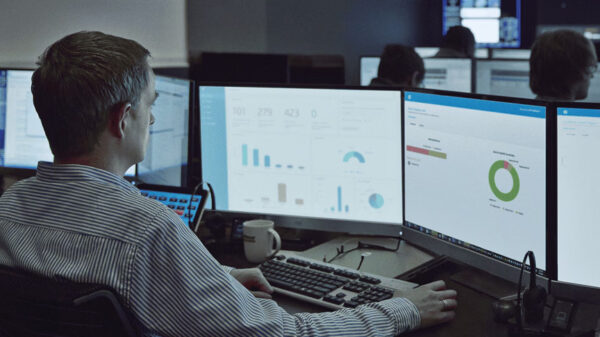

Growing Importance of Automation in The Philippines

Demand for automation and robotics continues to grow in the Philippines, particularly in the automotive, electronics and food & beverage industries.

Electronics is among the top export sectors in the Philippines, contributing USD 8.69 billion in the first quarter of 2018 and a high adopter of cobots.

The Philippines’ Department of Trade and Industry (DTI) recognises the importance of electronics and the manufacturing sector and, in line with Industry 4.0, has introduced the Inclusive Innovation Industrial Strategy or i3S to sustain the sector’s robust growth. i3S includes training and upscaling of skills, developing or adapting available technologies and improving operational efficiency to meet global demands and opportunities.

This is timely as the Philippines was ranked among the lowest in the region by the International Federation of Robotics for automation adoption with a robot density of three industrial robots installed per 10,000 employees in 2016, behind Singapore, Thailand and Malaysia.

Shermine Gotfredsen, General Manager, Southeast Asia and Oceania at Universal Robots, said: “Cobot demand is growing in the Philippines as automation is increasingly becoming a necessity for businesses to achieve greater production efficiencies amid rising operational costs, labour shortages and increasing competition. With the e-Series and G3 product lines, we now offer customers two distinct technology platforms, catering to a wider range of business needs,”she said.

End-user benefits

“End-users with complex applications and diverse or uncertain future needs will benefit from the e-Series platform and our unique Universal Robots+ ecosystem knowing that their investment will be able to grow with them as their needs change,” added von Hollen. “We enable innovative customers to rapidly drive adoption of automation technology into their businesses to maximise their competitive advantage.”

“The global cobot market is expected to continue to be one of the key growth drivers in the automation market the coming years. With the e-Series, my expectation is that we at Universal Robots will continue to leverage our position as the cobot market leader. This, however, can only be done by staying ahead technologically, hence the launch of e-Series,” said von Hollen, emphasising the importance of Universal Robots+ and the online training program Universal Robots Academy which will both support the e-Series platform.

The e-Series is now available. Universal Robots plans to begin shipping units to customers from 1 August 2018.