Autodesk, Inc. recently announced Autodesk SeeControl, a comprehensive new platform powering the Internet of Things that allows customers to capture, analyze and use data from remote products.

Acquired by Autodesk in September 2015, the new SeeControl offering will help manufacturers gain competitive advantage by optimizing their existing products and capturing the intelligence required to offer their customers innovative new services.

“The future of making products in the machinery and specialty vehicles industries is changing quickly and the expectations for online services have increased,” said Brian Roepke, senior director of Product Lifecycle Management and Internet of Things at Autodesk.

“The addition of SeeControl to the Autodesk line of IoT services will help businesses gain competitive advantage by optimizing existing products and capturing the necessary intelligence to offer their customers new services.”

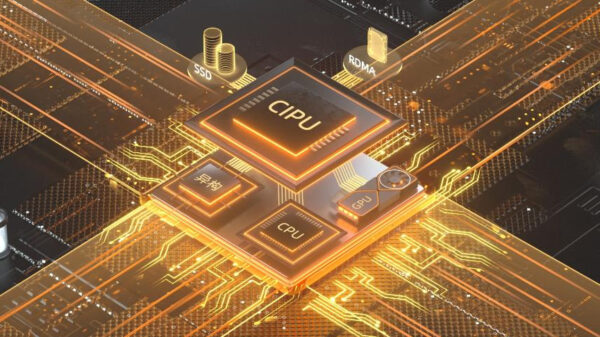

The Internet of Things refers to the growing ecosystem of physical things embedded with electronics, software, and sensors that are connected to the Internet and to each other.

When these things are products sold to end customers, manufacturers can gather and stream data about how they are being used to offer valuable insights, allowing them to respond to the needs of their markets and individual customers.

Connected products also create new insights for the people who design and make them, helping companies better understand their use and improve them over time.

For several years, manufacturers have been developing, manufacturing and bringing connected products to market using Autodesk cloud services like Fusion 360 and PLM 360. Now, with the addition of Autodesk SeeControl, the company has bolstered its cloud-based Product Innovation Platform with analytics that will enable its customers to achieve smarter, more predictive monitoring and achieve greater competitive separation.

Autodesk SeeControl allows manufacturers to monitor how their product performs in the real world and use live data to optimize future versions. They can keep products running at peak levels, identify potential for failure before it happens and schedule maintenance downtime when it is least disruptive.

Ultimately, manufacturers can bring their customers a level of enhanced services based on information about real world product performance and consumption.

SeeControl is a multi-tenant cloud solution, which allows companies to get up and running in minutes. It’s device and communication protocol agnostic, meaning companies are not tied to a single standard.

Autodesk claims SeeControl is easy to use, with no-coding and drag-and-drop tools for device communications, data analytics, visualization and business.

“Since the acquisition, Autodesk has moved aggressively to further develop SeeControl by connecting it with core Autodesk services such as 3D visualization,” said Roepke. “Bringing the live data from SeeControl into our engineering tools will better inform the next generation of designs and empower SeeControl customers in ways that weren’t previously possible before.”

“We’re excited about adopting Autodesk SeeControl because of the many ways it can help us grow our business and provide unparalleled service to our customers,” said David Keeley, Engineering Manager at TSM Control Systems. “In just a matter of days, we were able to connect to SeeControl and begin extracting value from live data collected from one of our products. We’re looking forward to what SeeControl will help us accomplish in the future.”