The development of printing technology continues its steadfast pace, with players aiming for faster print speeds, better quality prints, and low running cost. This is why global digital imaging leader Epson announced that it is increasing the production capacity of its PrecisionCore inkjet printheads.

PrecisionCore printheads, which offer fast print speeds and high image quality, are used primarily in office, commercial and industrial inkjet printers. The company is investing approximately 10 billion yen from the 2014 fiscal year (beginning April 1) through the 2015 fiscal year (ending March 31, 2015) in production lines at its Suwa Minami and Tohoku Epson PrecisionCore production sites in Japan.

Investment will total roughly 40 billion yen by fiscal 2015, including research and development spending and capital investment over the past decade.

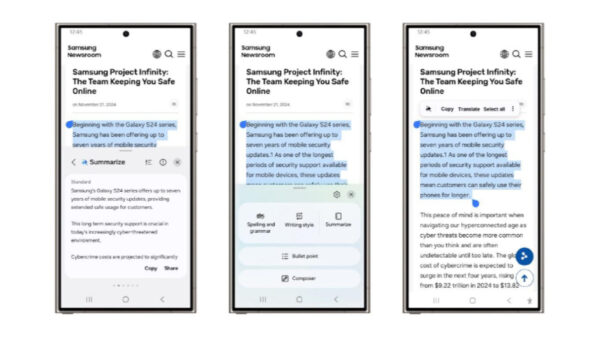

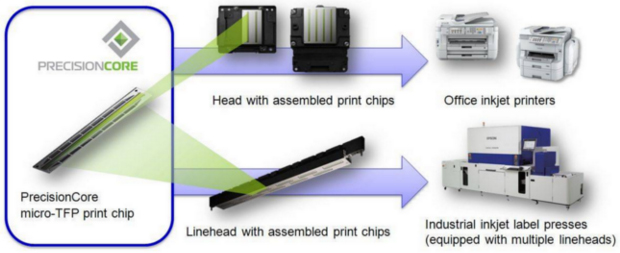

PrecisionCore is a collective designation for thin-film piezo print head technology that Epson developed by combining its core inkjet technology with advanced microelectromechanical systems (MEMS) technology. Put another way, PrecisionCore is evolutionary technology that is driving a transformation of inkjet printing.

Epson began producing PrecisionCore printheads in June 2013, on state-of-the-art production lines at the Suwa Minami Plant, in Nagano prefecture, and at Tohoku Epson, in Yamagata prefecture.

Ultra-precise core components that underpin our most powerful inkjet printer products, PrecisionCore printheads have individually controlled nozzles, each of which is capable of firing up to 50,000 precise ink droplets per second with astonishing accuracy. This level of precision and performance makes highly sophisticated technology essential for their production. To achieve both high quality and high throughput, Epson employs fully automated production lines that capitalize on Epson’s own industrial robots, as well as a combination of inkjet technology refined over two decades and microfabrication processes that are accurate to one one-thousandth of a millimeter.

By developing and producing PrecisionCore printheads entirely in Japan, Epson aims to accumulate technological expertise for next-generation printheads, build a base of production technology, and further increase the competitive advantage of its production sites in Japan that produce core components.

The investment in additional PrecisionCore production capacity is of critical significance, as it will enable Epson to achieve its business goal of strengthening its position and expanding its footprint in the inkjet printer domain. Going forward, Epson will promote the use of these powerful printheads and evolve them as a platform for a wide range of inkjet printer products so as to further enhance competitiveness and drive business growth.

Here in the Philippines, the printing industry is focused on providing the most value to customers. “This is where Epson is currently shining the most. Our L-Series – the first and only genuine ink tank system printer in the world – offers the lowest running cost against any printer in the market that uses genuine consumables. For only P295 per black ink bottle, a user can print up to 4,000 pages. This value, coupled with the stunning prints, reliability of the printer, and after-sales support, has propelled Epson to be the leader in value share in the inkjet printer market today,” said Epson Philippines’ product manager for inkjet printers, Russer Cabrera.