When creating animated visualizations for architects, there is no margin for error. Every detail must appear as it would in the real world for this exacting clientele. In order to achieve the highest level of polish in their scenes, Factory Fifteen makes extensive use of high-resolution 360-degree HDRI (high dynamic range image) libraries to set the stage for each of their projects. Just to position an HDRI into a scene so that it matches either the sun or digital lighting placement can take anywhere from 5-10 test renders, a process that kicked off each project with a minimum of 45-minutes worth of work on the CPU.

Moreover, all of Factory Fifteen’s projects require multiple test renders to ensure that shifts to lighting or materials in a given architectural model are hitting the mark. Running these test renders on the CPU would freeze a workstation for anywhere from 5-15 minutes at a time, dramatically impacting project continuity and as a result, limiting creative choices.

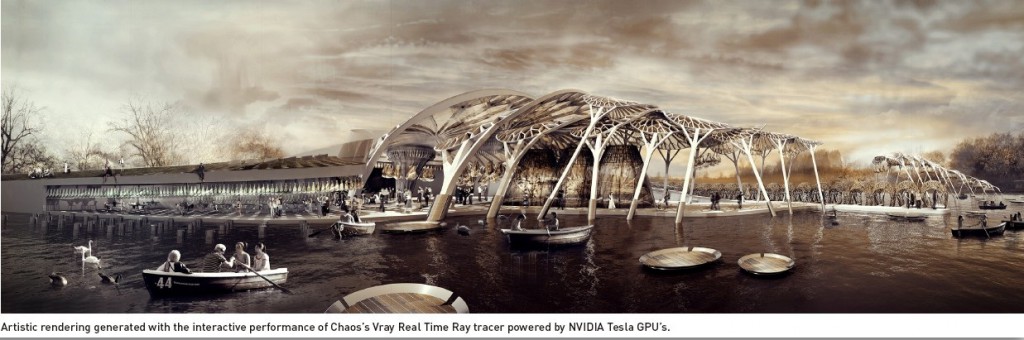

Factory Fifteen is a UK-based multidisciplinary film and animation studio specializing in architectural visualization for clients that include Knights Architects, Wilkinson Eyre Architects and MVRDV on projects ranging from Olympic stadiums to major bridges. The studio has won many awards for its work including Golden Age’s “Best Architectural 3D Film” and Megalomania’s “Best Architectural 3D Image.” Their architectural work has been featured in many leading architectural magazines, books and design blogs, and their film shorts have also been recognized by the Sundance Film Festival, SXSW, The Creator’s Project, The London Short Film Festival and others.

“Most of the time when lighting a scene, I can make up to 30+ test renders before I am happy with the result. Depending on file size and render times, this could take half a day to tweak on the CPU,” said Paul Nicholls, Co-Founder, Factory Fifteen. “The disadvantage of this method is that you get impatient and change multiple settings at once to limit the amount of test rendering you have to do. This can lead to not knowing exactly which changes worked and which didn’t—and ultimately you don’t feel like you’re 100% in control of the creative parameters you’re setting.”

Solution:

Nicholls had some previous experience with NVIDIA GPUs and thought that a dual-GPU Maximus system might help tackle the core pain points in Factory Fifteen’s workflow. Factory Fifteen installed an NVIDIA Maximus system, an HP Z820 workstation outfitted with NVIDIA Quadro 5000 and Tesla K20 GPUs.

NVIDIA Maximus technology combines the visualization and interactive design capability of NVIDIA Quadro GPUs and the high-performance computing power of NVIDIA Tesla GPUs in a single workstation.

“With the Maximus setup the feedback is so instant, I could make incremental changes separately and see the effects of a setting change in near real-time. For the first time I felt completely in control of the test render and its final look,” said Nicholls.

“Even more useful than lighting feedback was the material setup feedback I got with V-Ray RT running on Maximus. When creating complex realistic materials you create several maps for reflection, glossiness, bump and displacement. Each of those maps will separately need to be tweaked in material settings to get just the right look. This can be a tedious process of test rendering multiple times and you often change the settings without being able to preview how it might turn out. With Maximus I’ve been able to fine-tune scenes knowing how the changes would impact my projects rather than rendering blind—and it speeds up my process tenfold,” Nicholls continued.

Another benefit of working on Maximus is that it enables Factory Fifteen to instantly position HDRI images into scenes. On the CPU, Nichols and his team would have to load the images and rotate them by 15 degrees per test render until they accurately matched the lighting within a scene. On Maximus, HDRI placement happens instantly, saving at least 45 minutes at the front of every scene setup.

Impact:

Factory Fifteen artists can develop materials in Photoshop on one screen, and in real time see what the effect of those materials would be on a model in 3ds Max with a test render in V-Ray RT when working on a Maximus system. Additionally, there is no slowdown in the viewport while making modifications to a model.

“I have found that using V-Ray RT with Maximus has changed many of my usual 3D workflows,” explained Nicholls. “I can continue working within the model while having one of my other screens on the V-Ray RT window, so it’s allowed me to develop materials while modeling and setting up scenes.”

With Maximus, the near real-time feedback allows Nicholls and his team to make more incremental tweaks to lighting and materials with the flexibility to adjust materials and lighting details without freezing up entire workstations.

“The method of test rendering with the CPU and waiting for each render to finish before making another small adjustment to the render, lighting, or material settings now seems totally outdated,” concluded Nicholls.